When you buy through links on our articles, Future and its syndication partners may earn a commission.

Starliner, without its astronauts, will make a twilight landing on Earth under parachutes on Sept. 7 after fully undocking from the International Space Station during the evening of Sept. 6.

NASA astronauts Butch Wilmore and Suni Williams launched on Crew Flight Test, the first human launch with Boeing Starliner, on June 5. They were supposed to make a re-entry and landing on the spacecraft, but NASA elected to switch them onto SpaceX Crew Dragon for a February 2025 landing after problems arose with the Starliner propulsion system during docking that could not be resolved.

Starliner underwent some design changes after an issue with parachutes was uncovered in 2023. Before CFT launched, Space.com spoke with NASA’s Jim McMichael. McMichael is senior technical integration manager in the agency’s commercial crew program’s space operations mission directorate.

Build Boeing’s Starliner!

You can build your own Boeing Starliner space capsule with this Metal Earth Boeing CST-100 Starliner 3D Metal Model Kit, available for $10.95 at Amazon.

Related: Boeing’s 1st crewed Starliner to return to Earth without astronauts on Sept. 6

The interview took place at NASA’s Kennedy Space Center near Orlando shortly before a May 6 Starliner launch attempt later called off after technical issues with the United Launch Alliance Atlas V rocket; troubleshooting the Starliner helium leak delayed the launch to June 5. At the time of the interview, NASA and Boeing thought Starliner would land with astronauts on board.

This interview has been edited for clarity and condensed.

Space.com: What are your job duties?

McMichael: It’s basically the ultimate “other duties as assigned job.” It’s areas that need a little bit of extra integration, a little bit of extra help. I kind of move around. I’m actually a newbie. I’ve only been on this program for about two years. But most of that time, I’ve been working predominantly on the parachutes.

My background before that is I’ve worked a little bit on the SpaceX Dragon. In my previous jobs at NASA, I spent about 10 years on the [Lockheed Martin] Orion parachute development [for moon missions]. So, “parachutes” is kind of in my blood.

Space.com: What makes Starliner parachutes similar and different from Dragon or Orion?

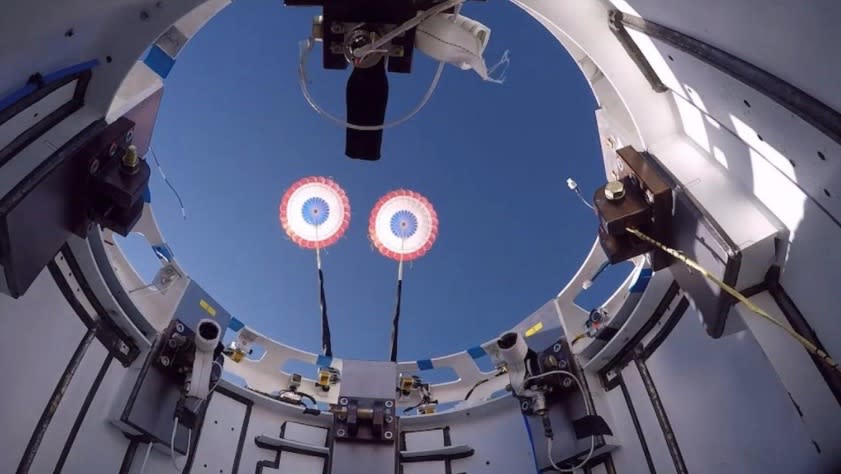

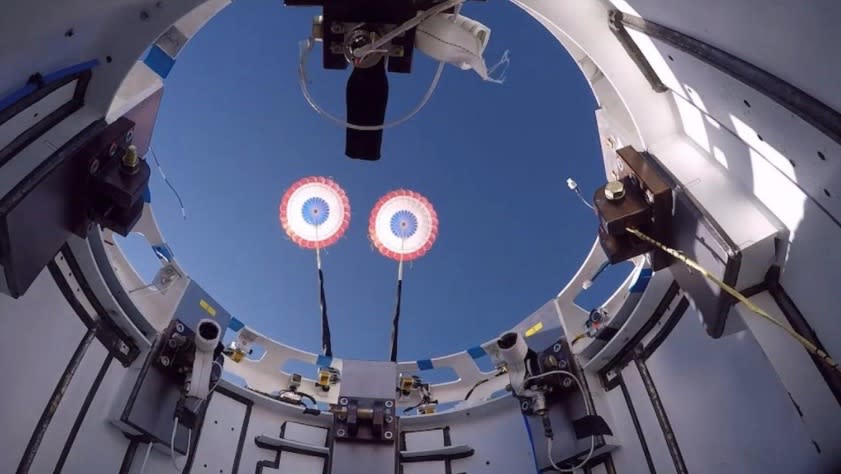

McMichael: The Boeing Starliner parachute system is actually a scaled version of the Orion system. It’s slightly smaller — because the capsule weighs a little bit less — but other than that, the architecture is very similar. There’s a forward heat shield on Boeing and on Orion, and they’re both removed by parachutes. The architecture is slightly different in how [the removal] is done. But once you get past that, then we have two drogue parachutes on each that are fired with mortars. Those are cut free. We have three pilot parachutes on each that pull out three mains on each.

The architecture [on Dragon] is slightly different, in that they fire the drogues with mortars, and then they just hold on to those drogues onto a single fitting. When they’re ready to transition from drogues to pilots, they don’t cut the drogues away and fire […] instead, they release the drogues and then the drogues themselves lift the main parachutes, to deploy them.

Related: See SpaceX’s Crew Dragon parachutes in action in this epic video compilation

Space.com: So if I can roll back about a year, to when you discovered the parachutes needed some more adjustments, I might call that Parachute 1.0. So today, is it a completely different parachute? Or is it sort of an adjusted parachute?

McMichael: The issue that we found last summer was called the” soft links.” They’re what attach the suspension lines. They are a primary link, and they carry the main load. When we found out those are an issue, we had already completed all of our qualification testing, if you will. So the trick there was we wanted to we needed to upgrade those, make them stronger and make a change to make the soft links better.

But we did not want to invalidate all of that testing that we had done up to that point. You get your data by testing the same system over and over again. So we didn’t want to start over because we didn’t want to throw away all that qualification test history.

McMichael: To be clear, the soft links that were in the system — those still had a positive margin. [In other words], they would not be expected to fail. It’s just that the margin was not as high as we wanted it to be because they are such a critical element. We actually carry a slightly higher margin on those because because we’ve got people on board. The soft links are the main load path; if you lost soft links, you lose the capability to carry load. On other pieces of the parachute […] You could blow out a panel, you could blow out a handful of panels, wouldn’t bother the parachute at all. Wouldn’t change its performance.

So, that was a change we made. Then while we were at it — the four most expensive words in the English language — there was also a new design change on the table to change the suspension line at the skirt to the parachute. But again, the trick there was, we wanted to make sure we didn’t invalidate all the expensive, hard, long testing that we’ve done in the past with these changes.

So, these were small changes. We then did a lot of ground testing to verify their strength. Then, we have subsequently done airdrop testing as well … It’s the law of unintended consequences that can bite you sometimes. We wanted to make sure there weren’t any unintended consequences of making these small changes.

Space.com: How are you starting to think ahead for Starliner-1, the first operational crewed mission expected in 2025?

McMichael: Parachutes take a lot of time to fabricate. They’re a long, long lead item, if you will, and then they get installed on the spacecraft pretty early — so, Starliner-1 parachutes are the same as what we’re flying today. Having said that, there’s a tiny delta of work that we have to do between CFT and Starliner-1.

The suspension lines themselves — the material as we buy it — you buy it in manufacturing lots. The manufacturing lot of suspension line material for Starliner-1 is a different lot than for CFT, so we need to check to make sure that that suspension line material is at least as strong and verify our margins again with the new suspension line material.

Spoiler alert: We have the data [from pull testing]. We’ve seen that the new suspension lines for Starliner-1 are actually slightly stronger. So we know we’re going to be fine. We just haven’t dotted the I’s and crossed the T’s on the paperwork yet.

Related: What’s next for Boeing Starliner after its 1st crew flight test?

We will very carefully inspect the CFT parachutes. That’s one of the things we’ll look at our in flight imagery. We’ll look at all the stills from the ground — we’ve got ground video as well, so we’ll look at how the chutes deployed. That doesn’t sound very scientific, but that’s a huge piece of looking at parachute performances: to just watch them to deploy is one of the big things we do.

Then when we recover them in the desert, we will inspect them carefully: every joint, every piece of apparel, every one of the parachutes. We will inspect to make sure there’s not any changes or anything unexpected. Very frequently, you end up with small tears, rips, torn things in a parachute. And that’s completely fine. It’s completely expected. So, we’ll do all those inspections, but [so far], we’re not expecting any changes.

RELATED STORIES:

— Boeing’s 1st crewed Starliner to return to Earth without astronauts on Sept. 6

— Boeing Starliner astronauts will return home on a SpaceX Dragon in 2025, NASA confirms

— Here’s what Boeing Starliner astronauts are doing on the ISS as NASA works on their ride home

Space.com: So as you’re on the parachute team, you’re not going to be relaxing until the very, very end.

McMichael: We joke that this entire spacecraft is just a way to deliver parachutes to orbit. But you’re right, we’re the last — way back in the day, Apollo did a video after all their testing was over about the Apollo parachute system. And the title of it was “Project Apollo: The Last 5 Miles Home.”

We really take that to heart, because the parachutes are the last five miles home. Earth is big in the windows. We deploy the mains at 8,000 feet [2.4 km]. In the overall scheme of having been to space, 8,000 feet is pretty close to the ground. We deploy the mains and it’s front and center: the big pretty picture of the crew module hanging off the main parachutes.

So, yeah, we don’t relax until we get the drogues […] and then once the mains all get inflated — we get full inflation on the three mains — then we can start breathing.