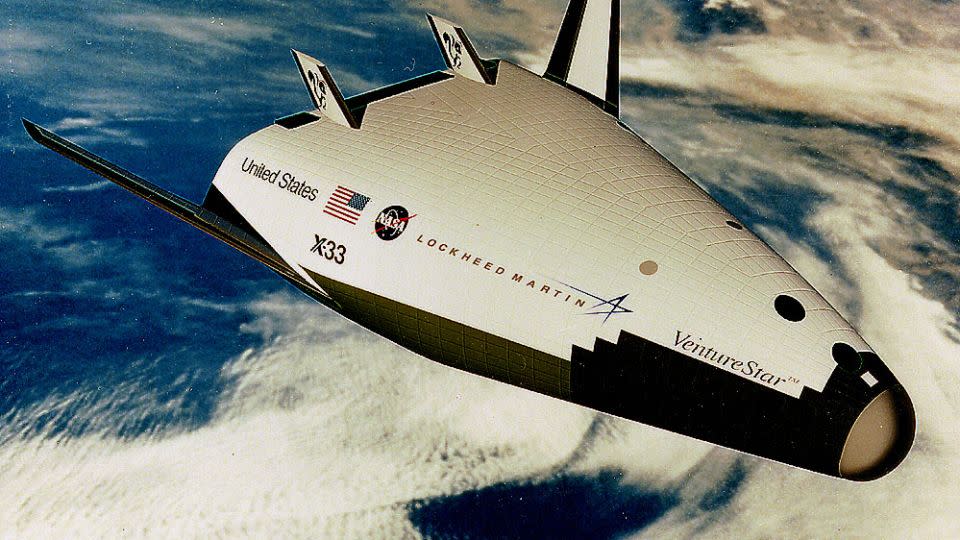

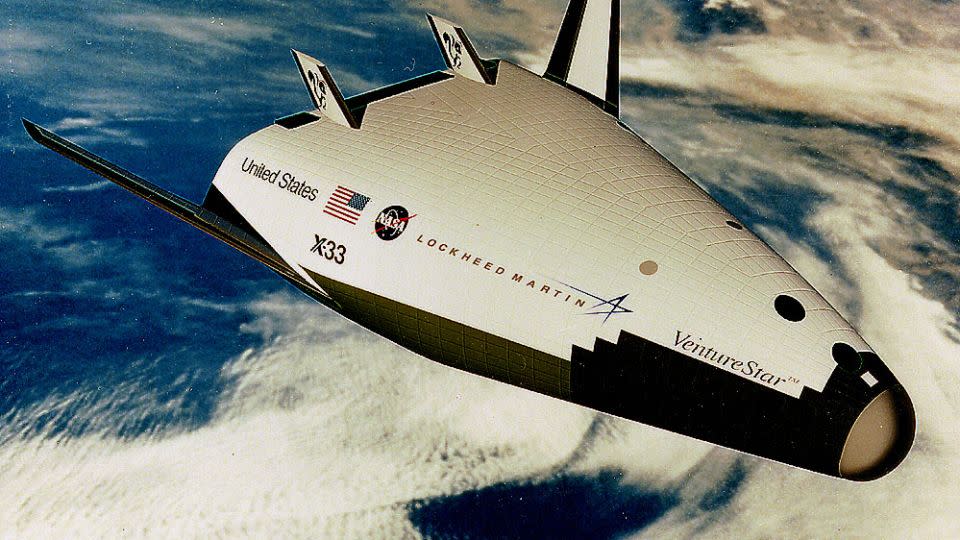

In the 1990s, NASA designed an experimental space plane meant to be a cost-effective alternative to expensive rockets.

Called the X-33, it was based on a concept called SSTO — or “single stage to orbit.” SSTO does away with the rocket stages of conventional space flight — where rockets containing engines and fuel and are dropped during ascent to shed weight — instead favoring a fully reusable single spacecraft.

The X-33 was designed to launch vertically like a rocket, but land on a runway like a plane, with the goal of reducing the cost of sending a pound of payload into orbit from $10,000 to just $1,000.

The program, however, was canceled in 2001 due to technical difficulties, adding to a list of similar projects that have failed to materialize.

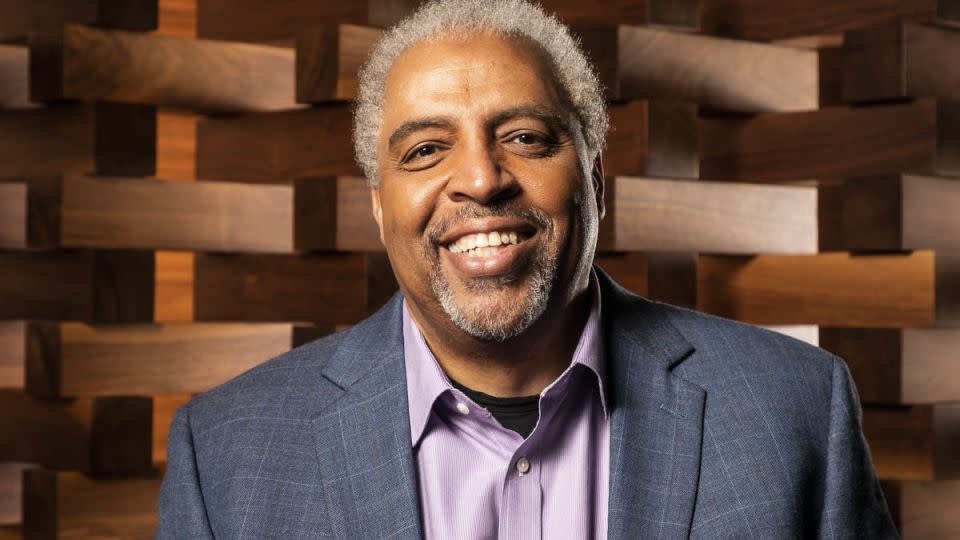

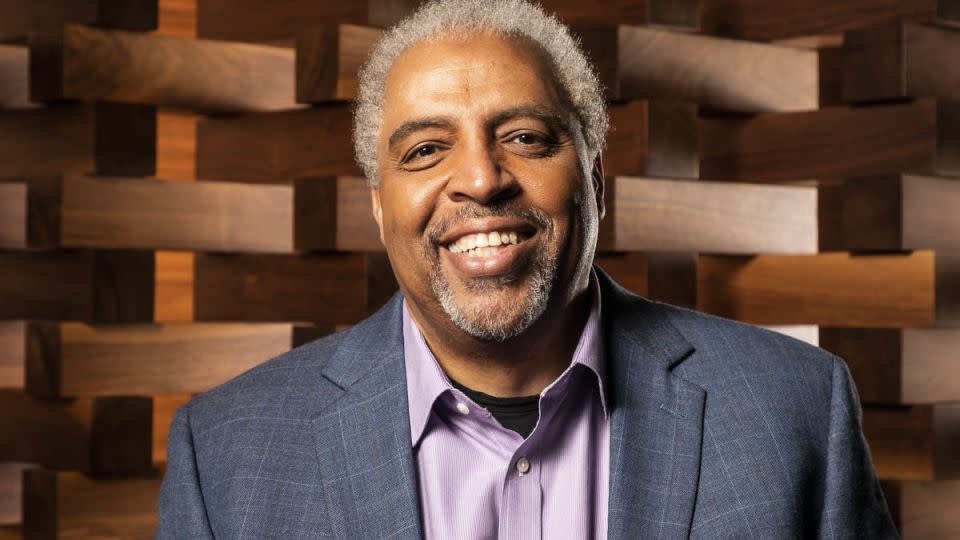

“I led the X-33 program, and we opted out of it because our assessment was that it was going to cost more than we were going to bargain for, and we were right at the edge of the technological capability to actually pull it off,” says Livingston Holder, an aerospace engineer, former USAF astronaut and program manager of X-33, and now CTO of Radian Aerospace — a Seattle-based company he co-founded in 2016 to revive the dream of the SSTO.

“Things have changed dramatically since the X-33 — we’ve got composite materials that are lighter, tougher and can take a larger thermal range than we had back then. And propulsion is better than anything we had, in terms of how efficiently it burns propellant and how much the systems weigh,” he says.

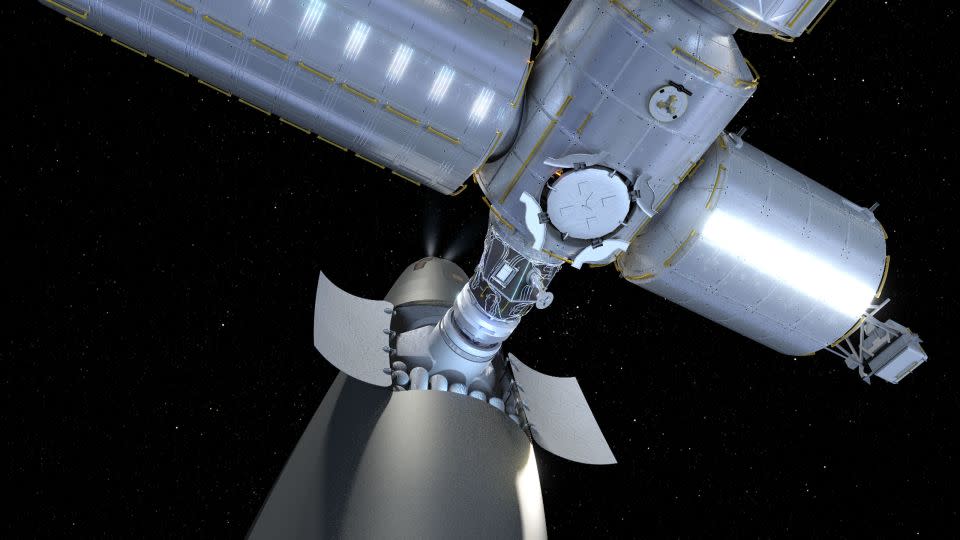

The product of this updated technology is the Radian One, a new space plane that will replace vertical launch with a very unusual system — a rocket-powered sled.

Wasteful stages

To be able to escape the Earth’s gravity and reach orbit, a rocket needs to reach a speed of about 17,500 miles per hour, according to Jeffrey Hoffman, a professor of aeronautics and astronautics at the Massachusetts Institute of Technology and a former NASA astronaut who has flown five Space Shuttle missions. “The problem is that as you’re going up, you don’t just have to lift the rocket and the payload, you also have to lift all of the fuel you’re carrying,” he says.

A rocket capable of reaching that velocity would need to devote 95% of its mass to fuel, Hoffman says, leaving very little room for everything else. “It’s been a dream to be able to get to orbit with one stage,” he adds. “But to do that, the structure of the rocket, the engines and the payload can’t be more than about 5% of the total mass of the whole system. And we just don’t know how to build stuff like that.”

That’s why all of the rockets ever used to reach orbit have been multi-stage, although current rockets like SpaceX’s Falcon 9 have fewer stages — two — than older ones like the Apollo moon mission’s Saturn V, which had three.

“Once you use up all the propellant from the first stage, rather than carrying that structure with you all the way up to orbit, you just drop it off. And that effectively allows you to take a lot more payload for a given mass sitting on the launch pad,” Hoffman explains.

Traditionally, the spent stages of rockets either fall back to Earth (usually in the ocean), burn up in the atmosphere or end up in orbit as space junk. SpaceX has changed that paradigm by designing reusable boosters that can autonomously land back on Earth. The premise of a single-stage space vehicle is to do away with the rocket stages entirely, with the promise to reduce costs even further.

It’s not easy to get around what Hoffman calls the “tyranny of the rocket equation,” or solving the problem of having to carry the weight of the fuel into space. Radian’s solution is a rocket-powered sled that runs along a two-mile rail and accelerates up to Mach 0.7 — 537 mph (864 kilometers per hour) — before releasing the space plane, which then flies into orbit under the power of its own engines.

“There have been various attempts to develop single stage to orbit vehicles,” Hoffman notes. “NASA and the Air Force tried it back in the late 1980s and 1990s. They tried to get around the problem by having what they call a scramjet engine, which would take the plane up through the atmosphere and burn oxygen from there rather than having to carry it with you. It’s a great idea but technically it’s really difficult to build that kind of an engine.”

“What Radian is doing with their rocket sled is sort of the equivalent of the scramjet,” Hoffman explains. “In other words, to try to get the initial acceleration without burning your rocket propellant. That way, you get around some of the limitations of the rocket equation.”

Space pick-up truck

Radian is convinced it can overcome the hurdles to a successful SSTO thanks to three key technologies.

The first is the sled launch system, which uses its fuel not just to power its own three engines, but also those on the space plane itself, leaving the space plane with a full tank right before takeoff. The second is the landing gear, which is designed only for landing rather than takeoff, which makes it significantly lighter. And the third is the wings, which are absent in a vertical rocket but reduce the amount of thrust required by the system, by providing lift when flying towards orbit.

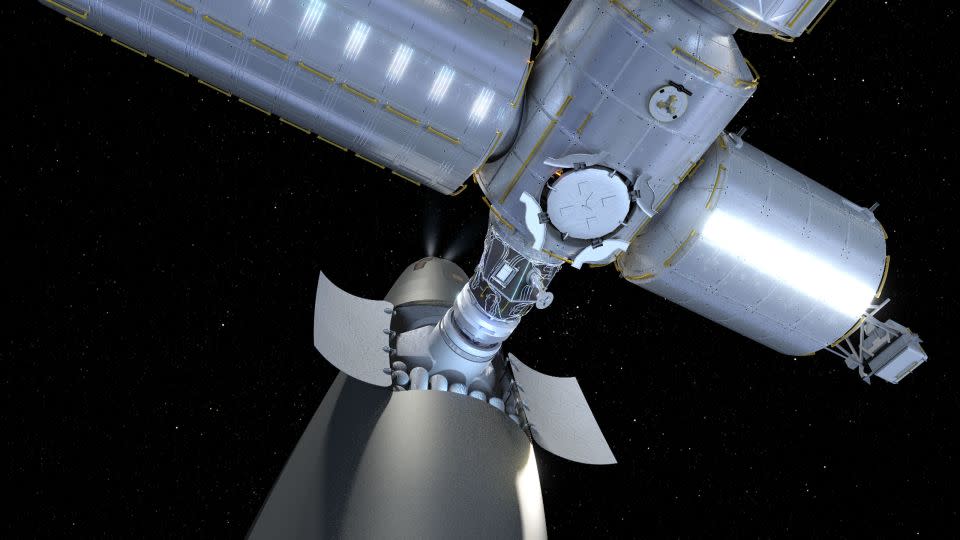

“Once we get to orbit, the closest analogy is probably the Space Shuttle,” Holder says. “We have a smaller bay, but we can perform many of the same types of missions. And when we fly home, we have a more robust composite exterior surface, and that allows us to reuse the system over and over again with diminished inspection requirements and faster turnaround times.”

Radian says its space plane will be reusable up to 100 times, carrying a crew of two to five astronauts with a 48-hour turnaround time between missions. A scale model of the plane will be tested this year, according to Holder, with a full-scale version beginning flight tests — without reaching orbit — in 2028.

Like the Shuttle, Radian One would be able to deploy payloads such as satellites into orbit, or perform missions using equipment that sits in the bay, such as Earth observations or surveillance and intelligence for defense or military entities. But, Holder adds, the plane could also help with humanitarian aid in disaster areas when runways, for example, have been rendered unusable — by dropping the payload out of the bay in a controlled re-entry through the atmosphere.

He traces an analogy with a construction site, where the rockets are the 18-wheelers pulling up with large equipment, and the Radian One is the pickup truck bringing smaller materials and the crew. “I think there’s always going to be a place for vertical launch rockets,” he adds. “They’re going to take the really heavy stuff up.”

He is aware of the skepticism that yet another SSTO attempt will face. The last such high-profile project to lose steam was Britain’s Skylon, a hydrogen-powered space plane intended to take off from a reinforced runway and land back on Earth. The company behind the project last year said that a two-stage-to-orbit system is now more likely.

“I don’t criticize the folks that scratch their heads and wonder whether single stage to orbit is viable,” Holder says. “It took me about a full year on this program to convince myself again that it is. You just have to be able to put yourself in the technology of today versus the technology of the past in order to see whether or not it’s viable.”

The big question, according to Hoffman, is not just whether SSTO can be technically achievable, but whether it can do so at a cost that is economically competitive with other launch systems, such as SpaceX’s new starship, which can take up hundreds of tiny payloads in one launch and do it relatively cheaply. “That’s always been the reason for going for the dream of single stage to orbit — in principle, it should be less expensive,” he said.

“I hope they’re successful,” Hoffman added. “Because it would definitely be a first, technically — and we’ll see about the economics. You never know until they demonstrate the capability and see who signs up to use it.”

For more CNN news and newsletters create an account at CNN.com